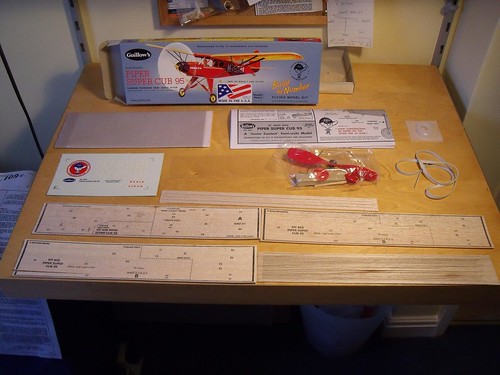

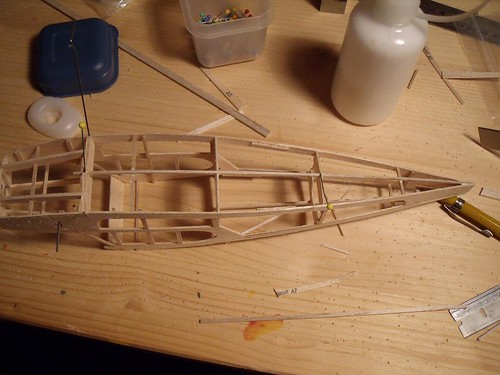

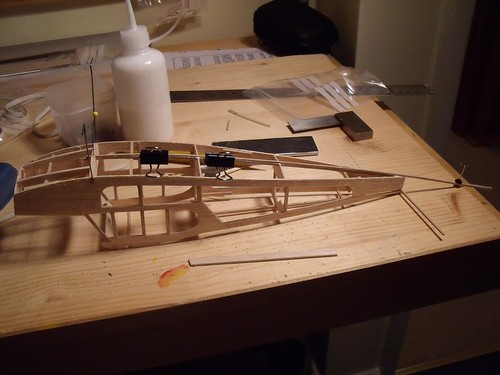

The kit is good value the balsa sheets are the lightest ever in a guillows kit (7.5lb) and it even has a reasobale sized prop!

The kit rubber is a bit on the rough side however it could probably make it fly. The only thing wrong with the kit is that 3 out of the four pieces of 1/4" strip actaully measure 3/16"! It is a pity really as the wood is ideal (nice and hard) for leading edges. I'll simply cut new strips for these from stock, but it would be a pity if someone bough this for their first kit and was let down by such a silly error