When you say "rolls" do you mean it turned on its axis that runs the length of the fuselage?

If that's the case, I don't know exactly how to fix it. I have a 900 series Mustang that I've been trying to trim and I think the trim tab I put on the left wing to keep it from spiraling into the ground to the left has actually put weight on that wing and increased its spiral. I added a trim tab (mostly for the weight) to the right wing as well as some down/right thrust and it's mostly corrected.

I have had questions about whether it's necessary to balance these airplanes laterally as well as from front to back. Maybe it's a balance issue?

500 Series Focke-Wulf FW-190 Build

37 posts

• Page 3 of 3 • 1, 2, 3

ADW,

That's called torque roll. What is happening is the force of the torque from the prop turning is rolling the plane over to the left. It is very common. There are a few things you can do combat this effect. First off I am assuming you have already balanced the model for proper CG and have done all of your glide tests to see that the stabilizer and wing have the proper incidence. You can and probably should already add some right thrust. Do this by adding a small piece scrap balsa as a shim between the nose block and the fuselage. I would suggest adding some more washout in the right wing panel only. This can be done on the field by breathing on the area you want to warp and twist in a little past where you want it to go. Hold it until it sets. This usually takes 30 seconds or so. give it a launch and see what happens. Just remember you will have to check this every time before you launch the plane as it will not stay permanently until you take it home and really wet the area and pin down to dry with the correct washout. The main thing is to try one change at a time. This way you can see what effect each change has on the plane. Please post your results.

Steve

That's called torque roll. What is happening is the force of the torque from the prop turning is rolling the plane over to the left. It is very common. There are a few things you can do combat this effect. First off I am assuming you have already balanced the model for proper CG and have done all of your glide tests to see that the stabilizer and wing have the proper incidence. You can and probably should already add some right thrust. Do this by adding a small piece scrap balsa as a shim between the nose block and the fuselage. I would suggest adding some more washout in the right wing panel only. This can be done on the field by breathing on the area you want to warp and twist in a little past where you want it to go. Hold it until it sets. This usually takes 30 seconds or so. give it a launch and see what happens. Just remember you will have to check this every time before you launch the plane as it will not stay permanently until you take it home and really wet the area and pin down to dry with the correct washout. The main thing is to try one change at a time. This way you can see what effect each change has on the plane. Please post your results.

Steve

- Steve Blanchard

- Posts: 343

- Joined: Tue Jun 14, 2011 10:08 am

I think i can also combat this by t using a larger prop (perhaps a peck prop) I believe a larger prop will result in fewer RPM, and i should also use one loop of 1/8" rubber, apposed to two loops of 3/32" rubber like i have.

- ADW 123

- Posts: 1158

- Joined: Mon Feb 22, 2010 5:22 pm

- Location: Cincinnati, Ohio

I switched out my 3/32" rubber with 1/8" rubber from an old peck kit i built. This rubber is very useful, and i believe it is FAI... now if only we could get guillows to supply useable rubber... (how hard can it be. seriously)

I went to the track field and wound up the rubber a good 450-500 times. i added a little bit of clay to the right wing tip to counteract the barrel roll the torque caused. about 4 or 5 flights in, I got a pretty decend 12 second flight out of it. i wish it could have been longer, but i think it was mainly due to the fact that my wulf came in at 45g ballanced! Using quality (or even half decent) wood would have resulted in longer flights but...

Here is a video of my best flight. You will have to put it into full screen to see the plane when it gets farther away.

http://s936.photobucket.com/albums/ad203/swaggerwarnera/?action=view¤t=IMG_0078.mp4

I went to the track field and wound up the rubber a good 450-500 times. i added a little bit of clay to the right wing tip to counteract the barrel roll the torque caused. about 4 or 5 flights in, I got a pretty decend 12 second flight out of it. i wish it could have been longer, but i think it was mainly due to the fact that my wulf came in at 45g ballanced! Using quality (or even half decent) wood would have resulted in longer flights but...

Here is a video of my best flight. You will have to put it into full screen to see the plane when it gets farther away.

http://s936.photobucket.com/albums/ad203/swaggerwarnera/?action=view¤t=IMG_0078.mp4

- ADW 123

- Posts: 1158

- Joined: Mon Feb 22, 2010 5:22 pm

- Location: Cincinnati, Ohio

I’m a big fan of the 500 Series. For what it’s worth I use two loops (four strands) 1/8 x 1.25 length , Peck Polymer propeller and a Reverse “S” Hook. Also I don’t think Guillow’s should put quality rubber in a kit. Rubber doesn’t really cost that much and they would have to use a middle of the road size. Nobody would end up being happy. ect, ect ect. I would like to see a better propeller and wood though.

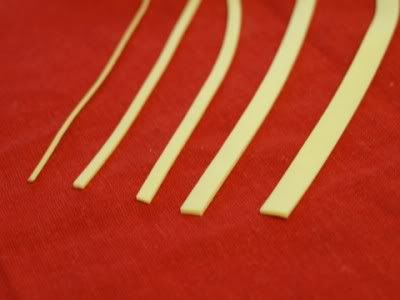

I like trim tabs better than wing weights. IMHO they are lighter and can be Trimmed (tuned) in better. If lets say the model is flying faster (more torque force from the motor) the wing will provide more counter lift and visa versa.

BTW how I do Trim Tabs is.,, I take a index card. I tape it on the wing. I than test glide and cut away the card. I repeat until I get a good glide and the correct size Trim Tab.

I like trim tabs better than wing weights. IMHO they are lighter and can be Trimmed (tuned) in better. If lets say the model is flying faster (more torque force from the motor) the wing will provide more counter lift and visa versa.

BTW how I do Trim Tabs is.,, I take a index card. I tape it on the wing. I than test glide and cut away the card. I repeat until I get a good glide and the correct size Trim Tab.

- WIDDOG

- Posts: 872

- Joined: Tue Aug 25, 2009 5:34 am

- Location: West Virginia USA

37 posts

• Page 3 of 3 • 1, 2, 3

Return to General Building Questions

Who is online

Users browsing this forum: No registered users and 3 guests